Understanding the Ultrasonic Flow Meter Working Principle

Ultrasonic flow meters have become essential tools in various industries, including water management, chemical processing, and HVAC systems. They offer a non-intrusive, highly accurate way to measure the flow rate of liquids and gases. Let’s dive deep into the ultrasonic flow meter working principle and highlight its advantages, applications, and technological innovations.

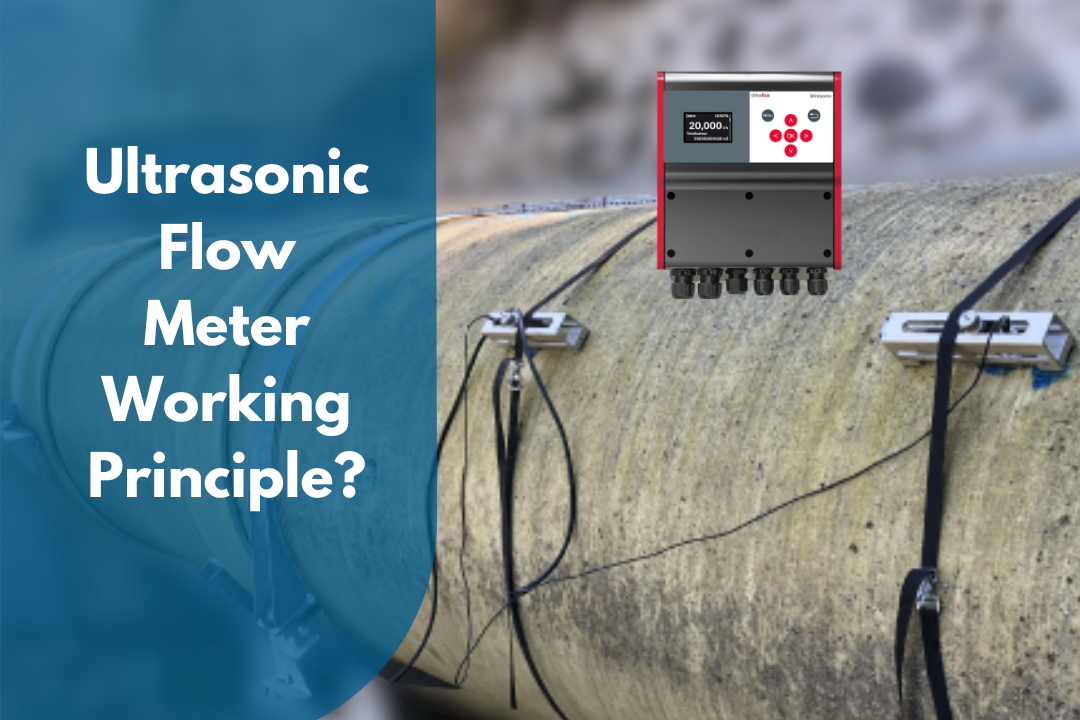

What is an Ultrasonic Flow Meter?

An ultrasonic flow meter is a device that measures the velocity of a fluid by using ultrasonic sound waves. Unlike conventional flow meters, ultrasonic flow meters operate without any moving parts, making them durable, low-maintenance, and ideal for applications requiring minimal downtime.

Ultrasonic Flow Meter Working Principle Explained

At its core, ultrasonic flow meter working principle is based on the transit time difference or Doppler effect principle. Let’s explore these mechanisms in detail:

- Time-of-Flight (Transit Time) Method

In this method, ultrasonic sound waves are transmitted and received by sensors placed on opposite sides of the pipe. Here’s how it works:- Two ultrasonic transducers act as both transmitters and receivers.

- Sound waves travel with the flow and against the flow.

- The difference in transit time between the two directions is proportional to the flow velocity.

- Using the flow velocity and pipe dimensions, the volumetric flow rate is calculated.

This method is highly accurate for clean fluids like water, oils, and certain chemicals.

- Doppler Effect Method

The Doppler method works by detecting the change in frequency of sound waves reflected off particles or bubbles within the fluid. Here’s how:- An ultrasonic wave is transmitted into the flow.

- If the fluid contains particulates or bubbles, these act as reflectors.

- The frequency shift between the transmitted and received signal is proportional to the flow velocity.

This method is ideal for slurries, wastewater, and other applications with entrained solids or gases.

Key Components of an Ultrasonic Flow Meter

- Transducers: Emit and receive ultrasonic signals. These can be clamp-on or wetted types, depending on the application.

- Processing Unit: Converts transit-time or frequency shift data into flow measurements.

- Display and Output Interfaces: Show real-time data and connect to SCADA systems for remote monitoring.

Advantages of Ultrasonic Flow Meters

- Non-Intrusive Measurement: Clamp-on models do not require pipe cutting or process interruption.

- Wide Application Range: Suitable for clean fluids, slurries, and even some gases.

- Accuracy: High precision with minimal calibration needs for time-of-flight models.

- Durability: No moving parts ensure long-term reliability and low maintenance.

- Cost-Effectiveness: Saves on installation costs, especially for retrofit applications.

Applications of Ultrasonic Flow Meters

- Water and Wastewater Management: Monitor flow rates in pipelines and treatment facilities.

- Oil and Gas Industry: Measure flow in crude oil, refined products, and natural gas pipelines.

- HVAC Systems: Optimize chilled water and heating loops for energy efficiency.

- Food and Beverage: Ensure accurate flow measurement in hygienic environments.

- Chemical Processing: Measure corrosive fluids without exposing sensors to harsh chemicals.

Innovations in Ultrasonic Flow Meter Technology

The latest advancements in ultrasonic flow meters include:

- Clamp-On Sensors with Enhanced Accuracy: Modern clamp-on sensors now rival wetted sensors in precision, making installation more flexible.

- Dual-Channel Technology: Improves measurement reliability by using two ultrasonic paths for better signal processing.

- Temperature Compensation: Ensures consistent readings in applications with temperature fluctuations.

- IoT Integration: Real-time data transfer to cloud platforms enables predictive maintenance and performance monitoring.

How to Choose the Right Ultrasonic Flow Meter

Selecting the right ultrasonic flow meter depends on several factors:

- Fluid Type: For clean fluids, go for time-of-flight models. For slurries or bubbles, opt for Doppler models.

- Pipe Size and Material: Ensure compatibility with your pipeline dimensions and materials.

- Temperature and Pressure Conditions: Choose a model rated for the operational conditions of your application.

- Required Outputs: Look for analog, digital, or wireless connectivity options.

Learn About Ultrasonic Flow Meter Working Principle

Understanding the working principle of ultrasonic flow meters reveals their versatility and efficiency in modern industrial applications. Whether you need precise measurements for clean water or robust performance for slurry applications, ultrasonic flow meters provide a reliable, low-maintenance solution.

By embracing the latest innovations and leveraging the right model for your needs, ultrasonic flow meters can significantly enhance process control, energy efficiency, and operational insights. Explore cutting-edge solutions today to optimize your flow measurement processes.